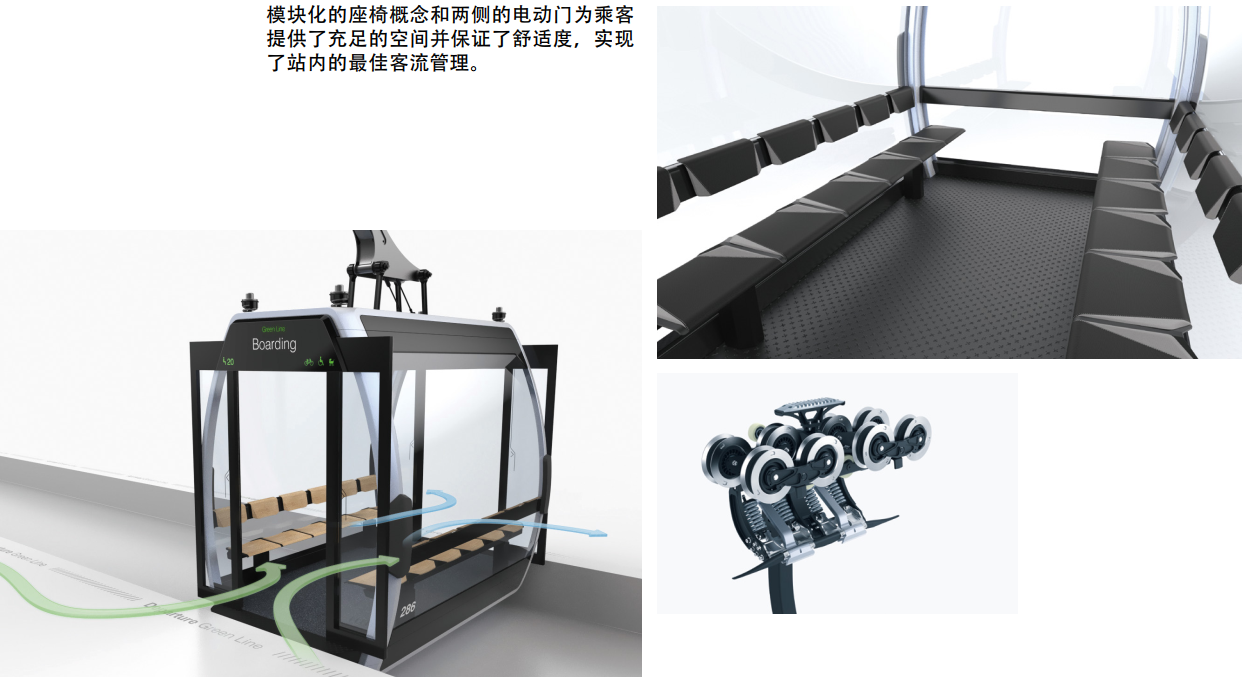

The Dobemaya TRI-Line ropeway is impressive with its large capacity, compact and visionary features. As an innovation in the cableway industry, it has a wide range of applications and is an ideal all-around product. Whether in winter sports, summer tourism or urban environments, TRI-Line can play its excellent performance, especially in the transportation planning aspect of TRI-Line with its advantages set a new benchmark.

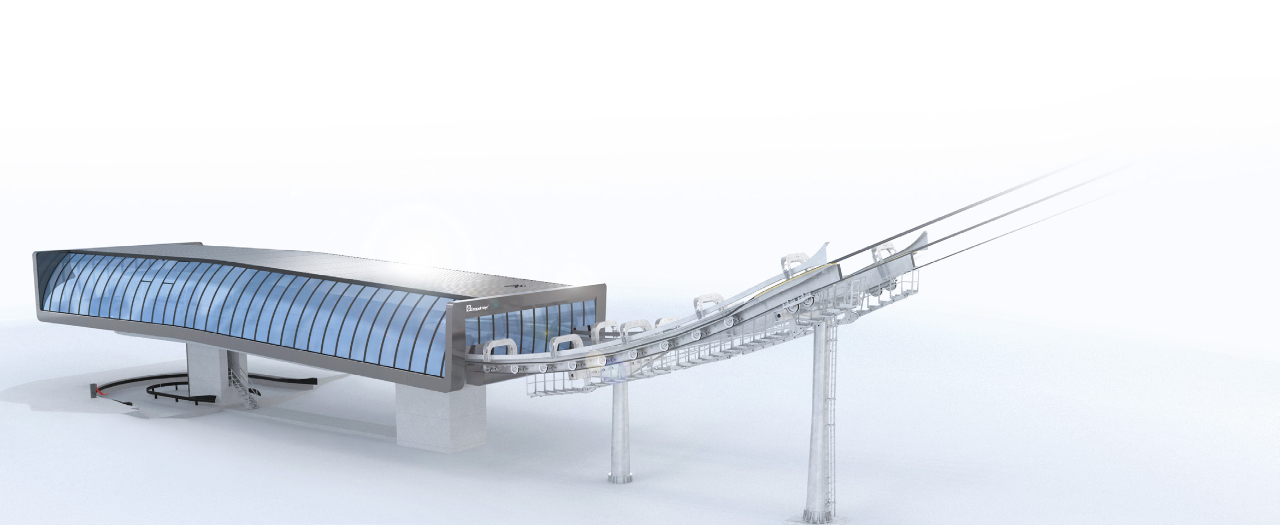

TRI-Line is a new ropeway system based on two proven ropeway systems (D-Line and 3S ropeway). It combines the strengths of the D-Line and 3S ropeway." "Explains Peter Luger, head of TRI-Line development at Dobemaya Wolford. Based on D-Line, TRI-Line is compact and requires less space and less time to build than a large 3S ropeway. In addition, mature D-Line components such as Dobemaya direct drive (DDD) can also be adapted to TRI-Line. Thanks to the stable operating conditions provided by the two load-bearing cables and the novel tow cable trolley, the TRI-Line has extremely strong wind stability. In addition, the TRI-Line has a columnar-shaped bracket, which is a great advantage in terms of installation, not only reducing the space required, but also allowing for helicopter lifting and quick installation.

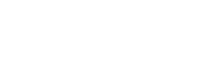

In terms of form and function, the new cab perfectly combines the advantages of OMEGA V and ATRIA, and the modular structure design is suitable for all usage scenarios. The new cabs can accommodate up to 20 people (12 seated and 8 standing) each, providing a comfortable space for four seasons of operation and urban transportation. In addition, the trolley is designed to be barrier-free and travels horizontally, with electric doors on both sides. The car doors on both sides can optimize the passenger flow in the station, which is especially suitable for urban transportation. TRI-Line achieves an amazing delivery capacity of up to 8,000 people/hour/one way. This also created a new standard in the ropeway industry. TRI-Line can also be used in the field of unmanned autonomous ropeway AURO.

At the heart of the TRI-Line's development was the novel trolley design, and the use of D-Line detractors was also key. "The individual components are simple and easy to maintain, and the in-station wire rope guide is sophisticated. All this makes it possible to apply D-Line's compact station house and its components to TRI-Line. From an engineering point of view, the new buggy is definitely a bright spot." Peter Luger.

The world's first TRI-Line is currently under construction in Hoch-Ybrig, Switzerland. It will replace a 55-year-old reciprocating aerial ropeway. The Hoch-Ybrig area attracts a large number of skiers and hikers from Zurich and the surrounding area every year. As a year-round tourist attraction, the ropeway plays an important role in providing a diverse range of activity facilities. "With the TRI-Line, we found a new ropeway system that met all of our needs at an attractive price. From a technical point of view, although single-line ropeway can be an option, it is unable to cope with the challenges brought by the special terrain, and it is very difficult to construct. Moreover, the 3S cableway cost far more than we had budgeted for. TRI-Line ropeway's excellent 3S performance and compact structure to handle extremely windy weather were decisive factors in choosing this system. The TRI-Line cableway is equipped with a new elevator with comfortable seats and wide glass Windows, which will greatly enhance passenger comfort." Hoch-Ybrig chief executive Urs Keller.